DBL Ceramics turns tile waste into classroom chalk for underserved schools

Published :

Updated :

DBL Ceramics, one of Bangladesh’s leading tile manufacturers, has launched the TileChalk initiative, transforming residue sludge from its tile manufacturing process into classroom chalk for underserved schools across Bangladesh, demonstrating how industrial innovation and sustainability can go hand in hand, according to a press release Monday.

Traditionally, chalk was made from organic materials and widely used in schools, but over time, it was largely replaced by plastic-based whiteboards and markers. With Bangladesh ranking as the sixth largest plastic-polluting country in the world, DBL Ceramics’ initiative provides a sustainable alternative that reduces industrial waste while reviving a valuable educational tool.

Known for its eco-conscious practices, DBL Ceramics operates water treatment plants that recycle 100 per cent of wastewater and follows zero-waste manufacturing practices. During water recycling at its ceramics plant, the company identified a unique type of residue sludge that could not be safely disposed of in landfills due to the risk of soil and water contamination.

Instead of discarding the material, the company saw an opportunity. Through six months of research and collaboration with chalk manufacturers, the residue sludge was re-engineered into high-quality chalk sticks that are safe, durable, and affordable to produce.

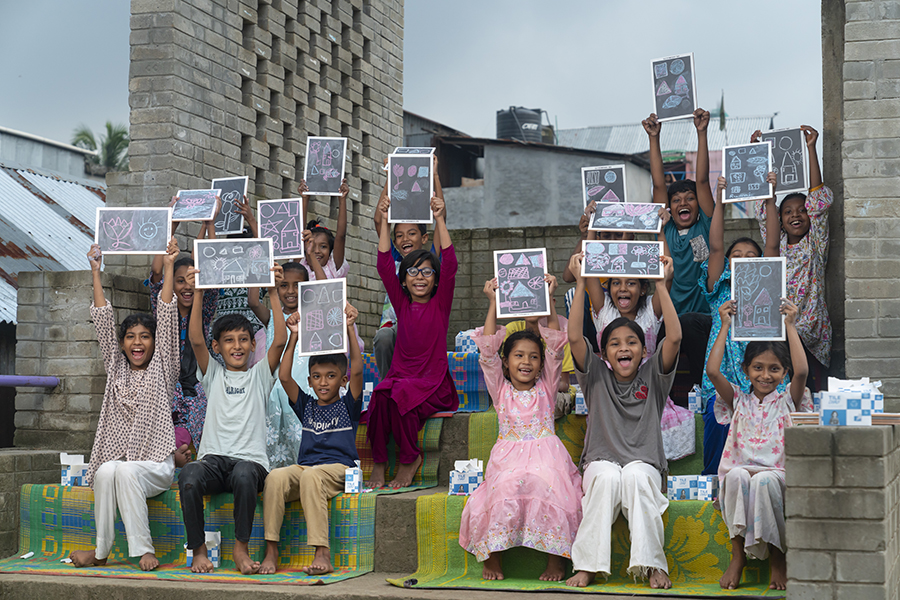

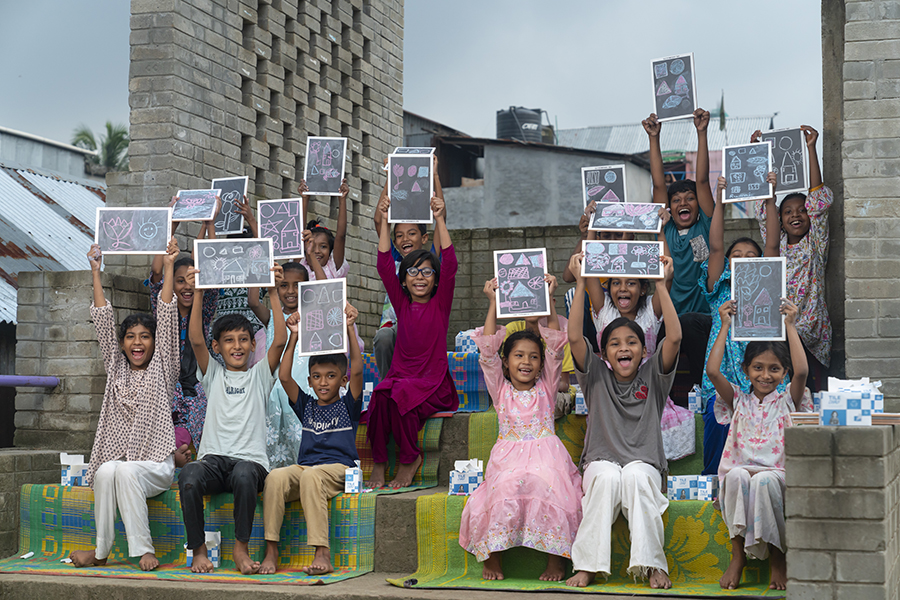

The first batch of 10,000 packets of TileChalk has been distributed through partner NGOs, reaching over 1,000 underserved schools, with plans for further expansion. Additionally, broken tiles have been repurposed into lightweight slates, reviving a sustainable classroom practice from the past. Together, these solutions reduce industrial waste while promoting environmentally responsible education.

“Education should never harm the environment,” said a DBL Ceramics spokesperson. “With TileChalk, we’ve turned waste into a resource that helps children learn while protecting the planet.”

To maximise the initiative’s impact, DBL Ceramics has made the TileChalk formula open-source and has encouraged competitors to adopt similar practices. The initiative has already gained attention from schools, NGOs, and media outlets, highlighting the potential for sustainability and social good to coexist in industrial manufacturing.

For all latest news, follow The Financial Express Google News channel.

For all latest news, follow The Financial Express Google News channel.