Published :

Updated :

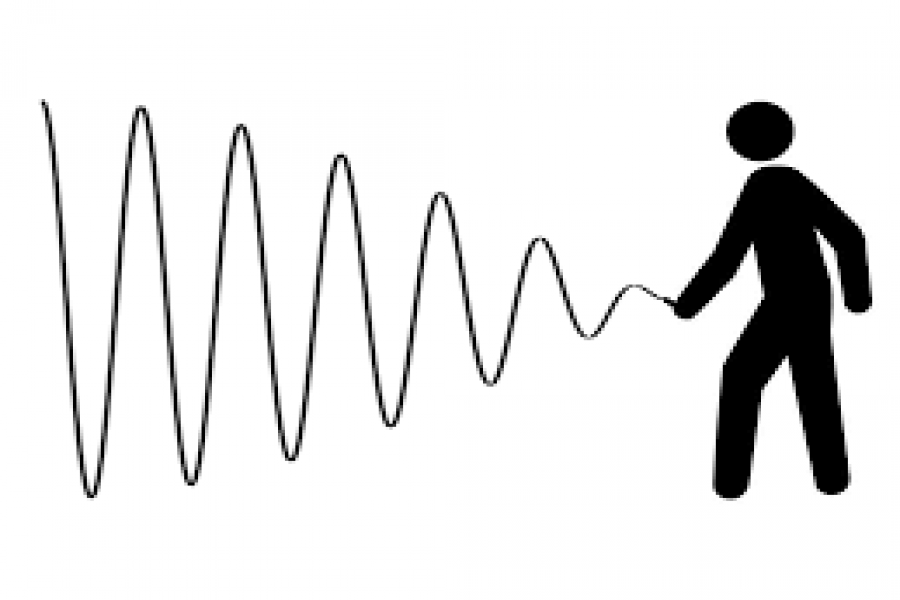

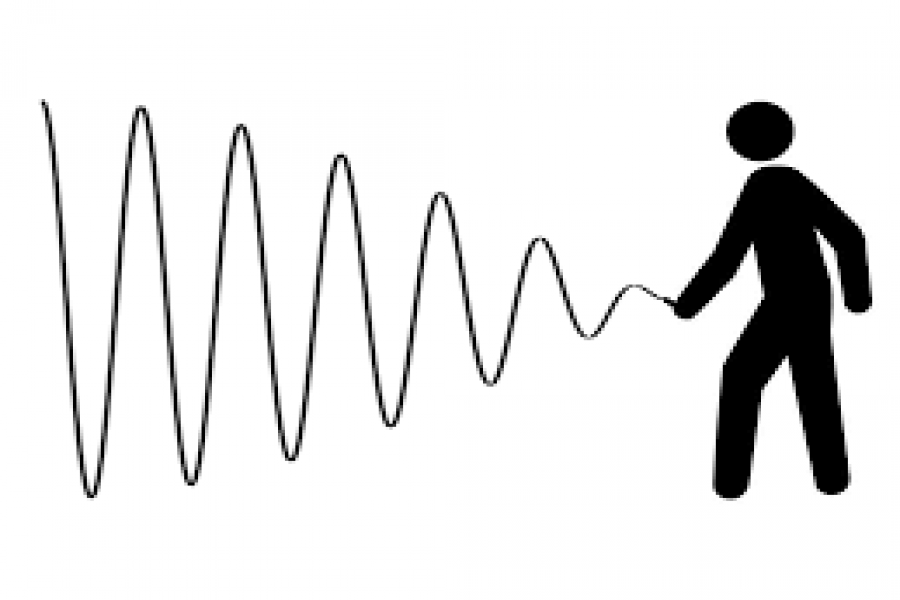

Over or surplus stock of inventory is a common phenomenon in our country. But very few of us know the reasons behind it. Jay Forrester named the reason 'bullwhip effect'. The effect occurs on the supply chain when changes in consumer demand cause companies in a supply chain to order more goods in order to meet perceived demand. The bullwhip effect usually flows down the supply chain, initiating with the retailer, wholesaler, distributor, manufacturer and then the raw materials supplier. It occurs when the demand for goods is based on demand forecasts from companies rather than considering actual consumer demand.

This concept has a severe impact on a country like Bangladesh where the demand-supply network is extremely complex due to regional variability, transportation issues, individual and small distributor-based model and lack of accurate information regarding actual market scenario. As giant organisations have proper analyst team and market researchers, they are less affected by this effect. But middle and small organisations, who are actually looking to grow and expand their business, are frequently affected by this phenomenon. The effect can be conveniently explained through the following example:

Bullwhip effect states that every member of supply chain relies upon each other. The manufacturer relies upon the feedback in terms of forecast from distributor; the distributor relies on wholesaler, who in turn relies upon retailer and so on. Suppose, one day, a consumer or a series of consumers prior to a football or cricket game place a huge order and completely liquidate the retailer's inventory of around 500 cases of beer. Let's say, prior to this transaction, the inventory for the retailer was 500 cases of beer for every two months. The retailer's anticipation is that we just sold 500 cases in one month and so, we are going to sell 500 cases per month moving forward. He now thinks that he will need to order 1,000 cases of beer (for two months) and he places this order to the wholesaler. After getting the increased order, the wholesaler himself order 1,500 cases from the distributor. The distributor says, "This is fantastic! Demand is increasing. We need to order more." He in turn orders 2,000 cases from the manufacturer. As the cycle continues, manufacturer ends up ordering more raw materials from the supplier. But when the next month rolls in, the sales of the distributor may dwindle to 250 cases - thereby leading those extra cases to gather dust on the shelves.

From retailer to manufacturer, everybody's inventory is higher than it was before. This is why, it is called bullwhip effect. In this process, single and certain change in demand has a huge impact across the entire supply chain process.

Companies can avoid this in their inventory situation by paying attention to:

- Business cycles: There are some companies who tend to have some quarters, which are busier than others.

- Seasonality: There are certain times in a year when demand may increase.

- New product introductions: In this case, company needs to be more prompt and aware as they don't have any previous data.

- End of life of a product: When a manufacturer decides to stop manufacturing a product, there can be a high demand for it as people rush to buy the products available.

- Unforeseen circumstances: No one can correctly estimate drastic increase in demand.

- Information sharing: Whenever there is an uneven rise of demand, the information behind it should be investigated and shared through the supply chain partners.

The mentioned steps can ensure that a smooth and prompt inventory system is maintained by everyone in the supply chain.

Saddam Hossain is with the Supply Chain Management Department of ACI Limited.

For all latest news, follow The Financial Express Google News channel.

For all latest news, follow The Financial Express Google News channel.